Right now, there are more than 5000+ job advertisements, globally, for keywords “Finite Element Analysis (FEA)” and “Computer Aided Engineering (CAE)”. The pay for these jobs are spiking up and the demand too is increasing at an insane rate.

The reason is simple. Almost all companies have realized the importance of simulation-assisted design processes. They are figuring out ways to incorporate simulation in their product development lifecycle and need skilled people who can help them do that.

But here’s the catch.

Companies want people who understand the bigger picture of things and adapt to the ever-changing landscape of product design. Not someone who knows the theory but finds it difficult to apply it in real life.

This course is exactly intended to bridge that gap between FEM theory and application

I will take you through different steps in Finite Element Analysis from a practical perspective. It is going to be fully application-oriented and I will present some case studies from the industry that will give you an idea of how industry professionals break down complicated problems into small chunks and then solve them gradually. I will also talk about the physical meaning of a lot of commonly misunderstood terms and terminologies in FEA. It’s always teamwork going ahead and these terminologies would help you to communicate effectively with other FE Analysts and design engineers in your team.

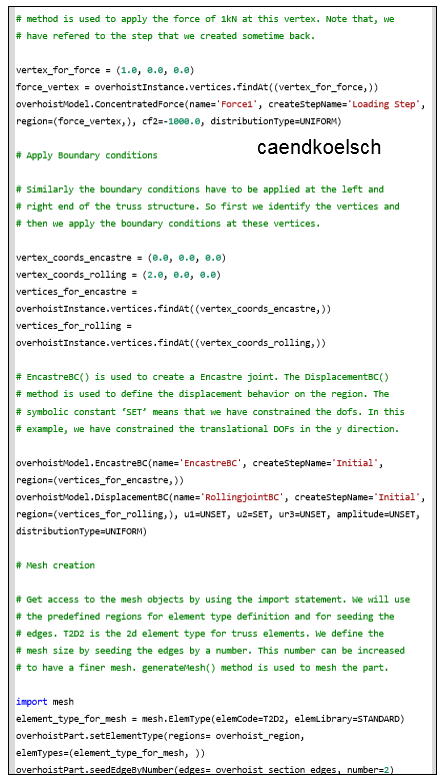

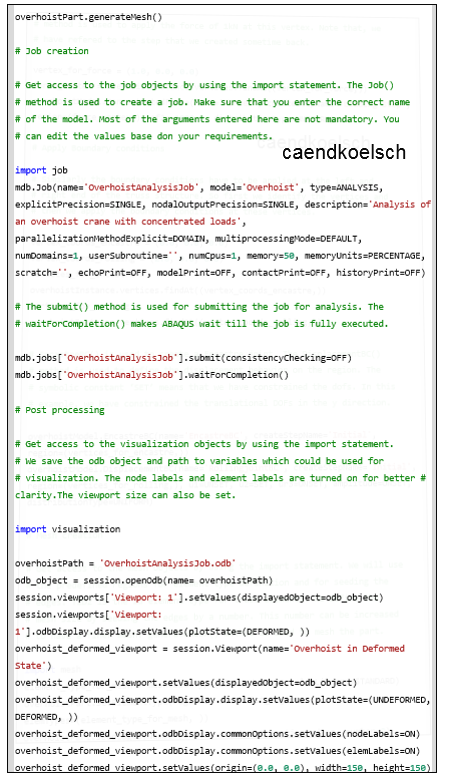

Then, I will introduce a framework for Python scripting that could be used for simulating problems with ABAQUS. I will use this framework to help you write Python scripts for 4 different problems and solve it using ABAQUS.

Let me go ahead and reveal a secret. If you are not going to be a FEM tool developer, you don’t need all the math that is being taught at the university or being described in detail in standard FEM textbooks. Rather, you need a clear and conceptual understanding of the concepts of FEA and then the aptitude to select and use the right tools from the commercially available FEA packages.

That will be this course’s contribution to you.

Towards the end of the course, I will also reveal some tips to prepare your career for landing a job as a FE Analyst.

What are you waiting for? Act now and get yourself certified with this course.

Who is this course for?

- Mechanical / Civil Engineering students who want to understand FEA in a practical way without getting bombarded with complicated math

- Beginner FE Analysts from the industry who want to apply FEA right away in their work routine

- Design engineers looking to transition into a FE Analyst role

- Engineers who want a framework for using Python Scripting in ABAQUS to increase productivity

- Managers who want to understand the bigger picture of FEA before decision making

- Technical Sales Professionals who want to be sure about the fundamentals of important terms used in FEA

- Small or medium sized companies who are short on manpower and time and who want to quickly ramp up their understanding of FEA

What you’ll learn?

- Understand the fundamentals of Finite Element Analysis (FEA) from a practical perspective without complicated math or equations

- Top-down and Bottom-up approach in FEA

- Steps in a FE Analysis and Examples of FE Applications

- Assumptions, Advantages and Limitations of FEA

- Types of FE Analysis: Static, Dynamic, Modal, Fatigue, Thermal, Heat transfer

- Using Symmetry, Plane Strain and Plane Strain conditions

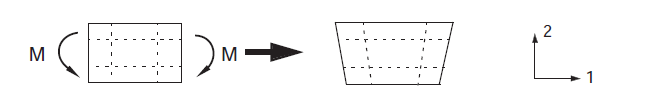

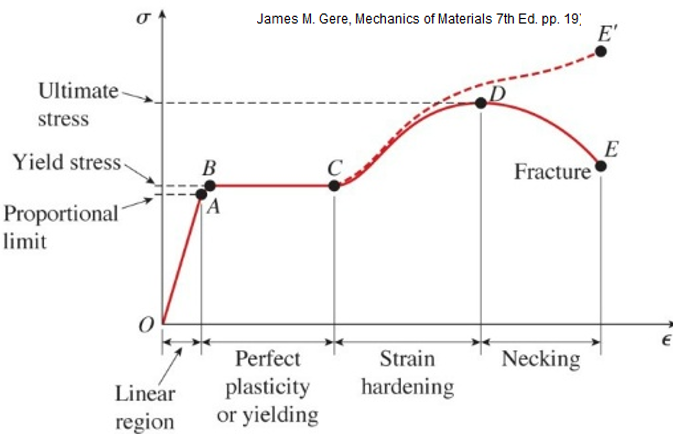

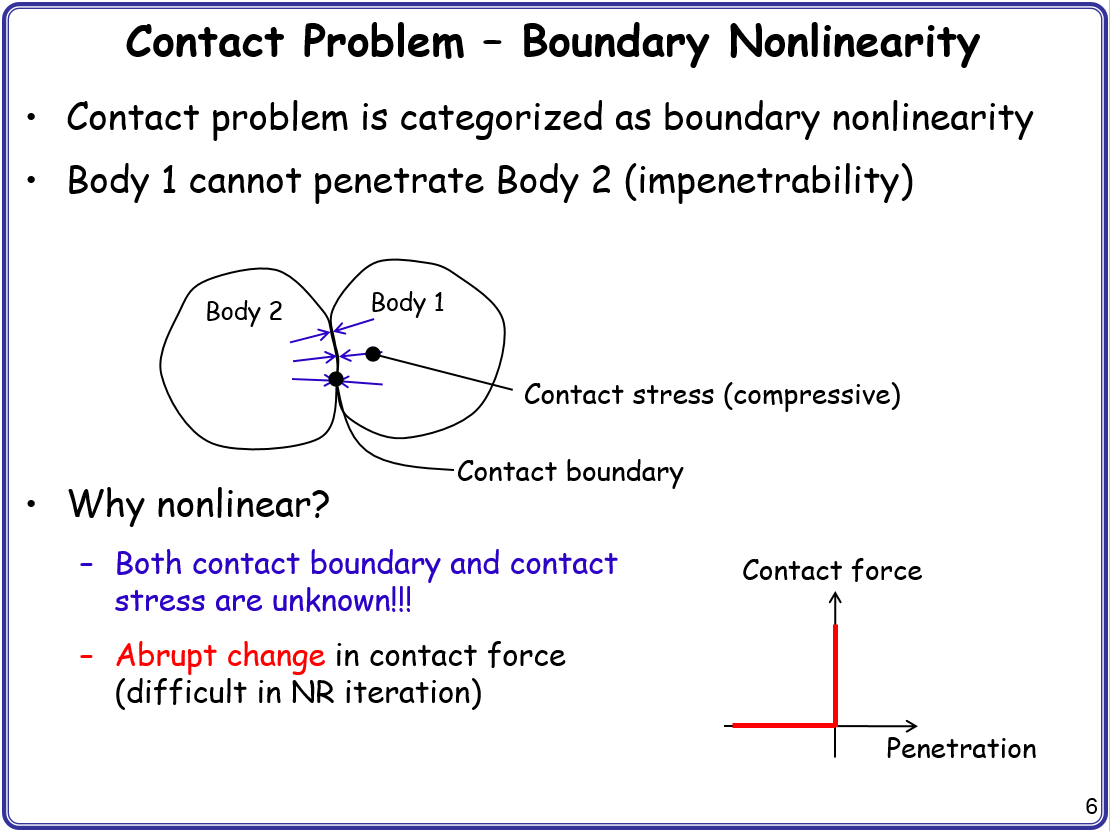

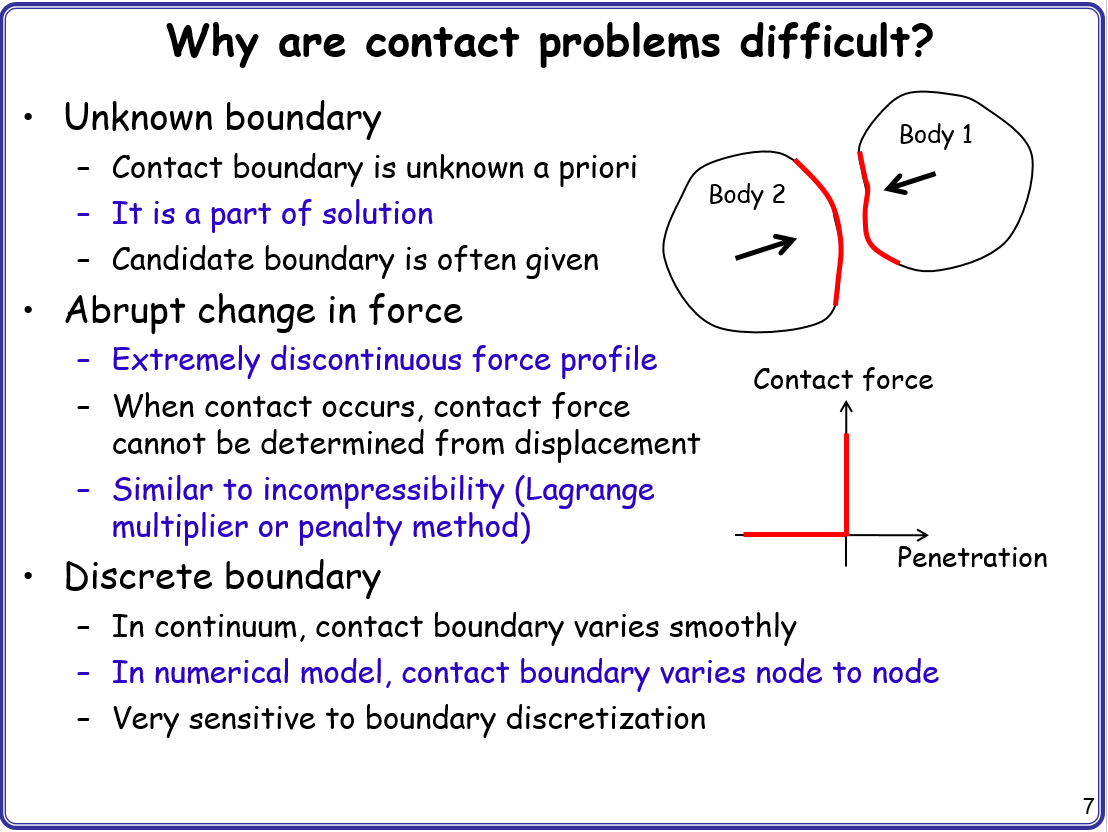

- What is Geometric-nonlinearity and when to use it

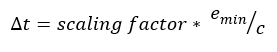

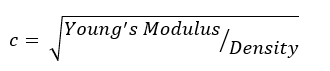

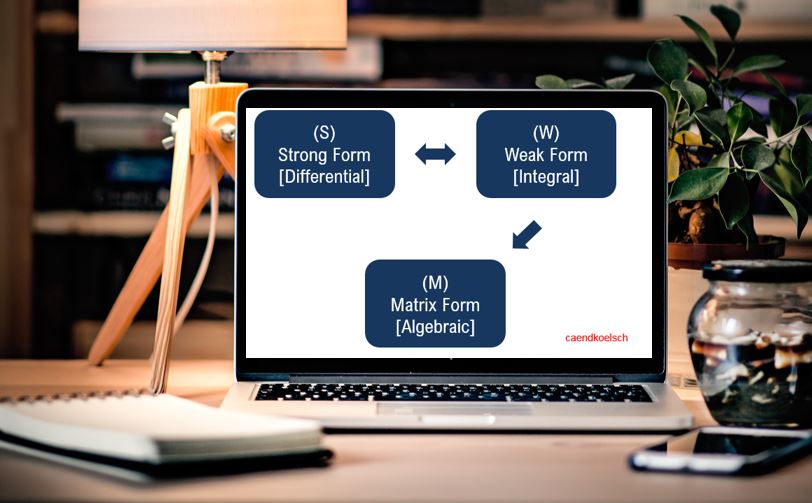

- Difference between strong forms and weak forms in FEA

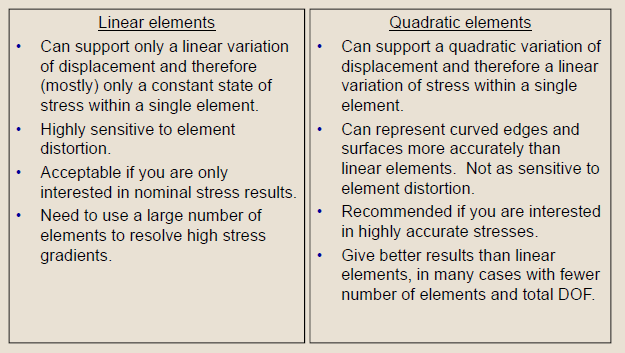

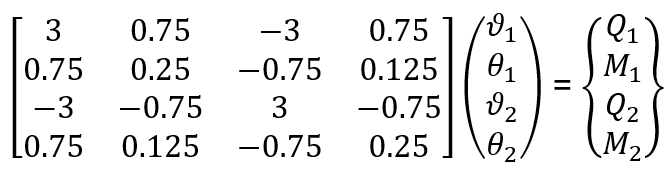

- Types of elements and coordinate systems

- Difference between Plate, Shell and Membrane Elements

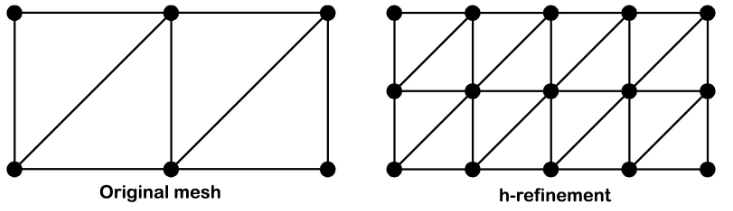

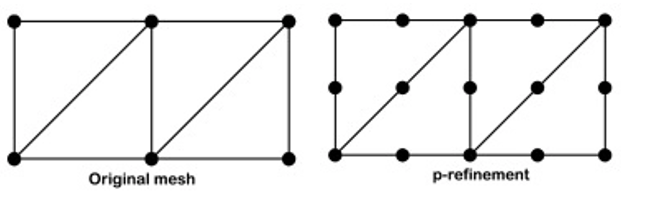

- Meshing: Quality check and Convergence

- Difference between h and p method

- Physical meaning of full and reduced integration

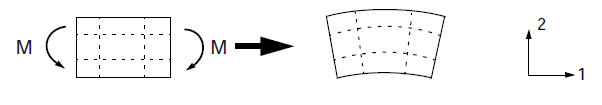

- What do shear locking and hourglassing mean in a practical context?

- Difference between essential and natural boundary conditions

- Direct and Iterative solvers: What’s the difference?

- Verification and validation in simulation

- Error Sources in FEM

- Industrial Case Study: Static Characteristics of a milling machine

- Industrial Case Study: FE Analysis of a slewing bearing of a wind turbine

- 6 things to consider before starting any FEA and a generic problem solving methodology

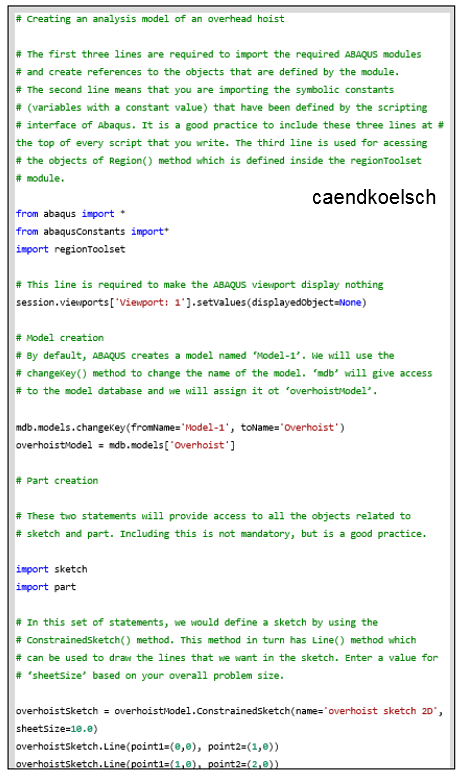

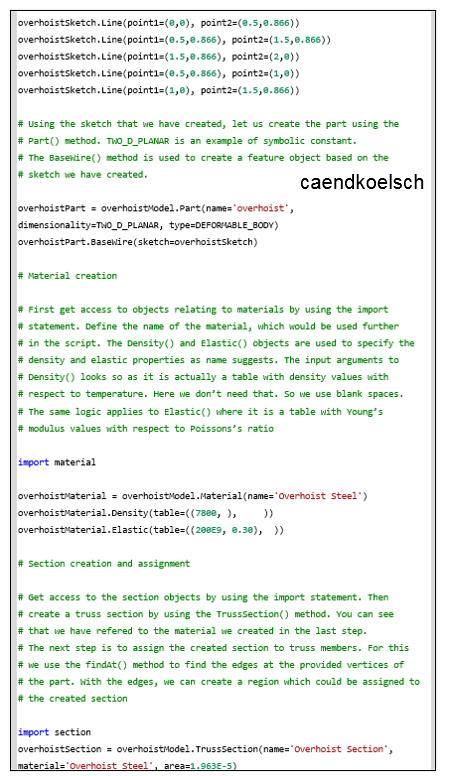

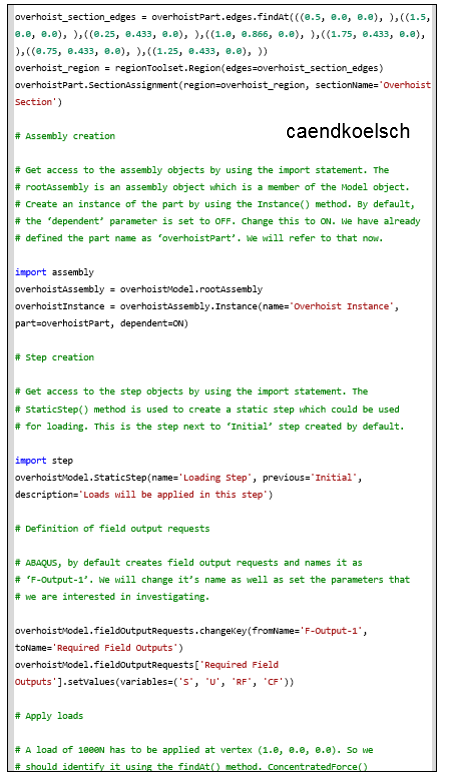

- Introduction to Python Scripting in ABAQUS and a general workflow for running a Python Script in ABAQUS

- A higher level understanding of Python Scripting methodology for ABAQUS

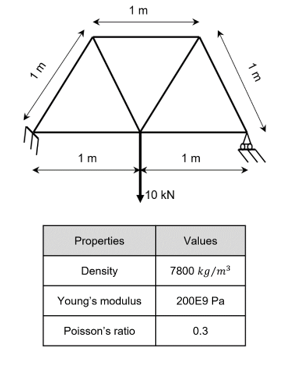

- Example 1: Python Scripting of a static analysis of a truss

- Example 2: Python Scripting of a deflection analysis of a cantilever beam

- Example 3: Python Scripting of a steady state thermal analysis

- Example 4: Python Scripting of a truss parameterization problem

- FEA in 2021: What to expect

- Communicate effectively with all stakeholders of a product design process

- How to mold your thought process as a student to get a job in FEA

- Understand how to accumulate that “experience” that big companies want before they hire you

- How to get an insider perspective and get hired as a FE Analyst

Requirements

- Basic knowledge of Mechanical / Civil engineering. There will be no math in this course

- Any text editor. I use Notepad++ because it’s free and doesn’t occupy much space. You can choose your own text editor

- Student version of ABAQUS is sufficient