I was casually skimming my university study material for getting a grasp of some concepts. Strangely, geometric nonlinearity was not discussed in-depth compared to other types of nonlinearities. I too had no applications or reasons at that point in time to dive deeper into this topic.

Fast forward a few years. Now, as I was interested(rather, had to!) to know more about geometric nonlinearities and its impact in the predictions of an FE analysis, I carried out a literature survey to get a better understanding.

I also found a couple of blogs that had a practical and concise explanation(I will provide the links to them at the end of this article).

Through this article, I will share what I learned. Of course, in a simplified and non-mathematical way, like my other blog articles. Please do register your comments or questions below the article if you have any.

So, let’s get started!

================================

Part 1

================================

What is geometric nonlinearity?

For simple structural analysis problems, engineers assume that the displacement or rotation in the geometry is usually very small. This might sound ironic as the objective of the analysis is to find the displacement. But still, this is a good assumption and makes the analysis computationally less expensive.

In certain cases, the load on the geometry becomes high that the geometry has to undergo larger quantities of displacement or rotation in order to maintain the equilibrium of the structure. These are clearly geometrically nonlinear situations.

In terms of stiffness (remember the legendary equation {F} = [K] {u}, F is the nodal load vector, K is the stiffness matrix and u, the nodal displacement vector), one has to consider geometric nonlinearity when the stiffness of the part changes significantly during the deformation process because of change in geometry.

Let’s look at an everyday example where the effects of nonlinear geometry should be considered.

Figure 1: Imagine the person on the right to be sitting on the chair [1]. Will the chair endure? The first ten people who guess the correct answer will get free tickets to the island where the fat guy is enjoying the pizza.

In this case, if you intend to do an all-load-case FE analysis for the chair, you should consider nonlinear geometry.

Now, how small is “small displacement”? Can we quantify it? This is a question that needs to be answered with sound engineering judgment of the problem. Also, some thumb rules followed by FE analysts come to our rescue.

Thumb rule 1: If you are finding the deflection of a beam and the results show that the deflection is more than half of the beam thickness, then it is a must to consider geometric nonlinearity.

Thumb rule 2: Also check the strain in the model. If they are more than 5%, the geometric nonlinearity cannot be ignored.

Thumb rule 3: If the strain versus displacement relation is nonlinear, then consider geometric nonlinearity

Thumb rule 4: If the deformation is greater than 1/20th of the component’s largest dimension, then consider geometric nonlinearity

But be aware that these are just thumb rules and not theorems that can be quoted. You will have to understand the problem, visualize how the results would be and then arrive at a judgment of considering or ignoring geometric nonlinearity.

Some examples:

Buckling is a good example of geometric nonlinearity.

To know more about linear and nonlinear buckling, check this informative article.

https://www.digitalengineering247.com/article/linear-and-nonlinear-buckling-in-fea/

Source: Wikipedia

Consider a simply supported beam. And a beam with both ends pinned. Now if there is a vertical load (perpendicular to the beam axis) acting on the beam’s midpoint, there will be no difference in the predicted displacement if geometric linearity is assumed and the forces are less.

If the load on the beam is increased significantly and geometric nonlinearity is considered, the vertical deformation in the two-end-fixed beam will be smaller compared to the simply supported beam. This is because there exists an axial force which reduces the vertical deformation in order to maintain the equilibrium.

To understand this phenomenon with a real-life example, visit this blog.

https://enterfea.com/geometrically-nonlinear-analysis-introduction/

I wish I had read this long time back.

The blog’s author has also made a flowchart (Figure 2) for deciding when to consider geometric nonlinearity.

Figure 2: Flowchart for deciding geometric nonlinearity [2]

Why do people use linear analysis then?

Can you give some more examples where one has to pay attention and consider geometric nonlinearity?

Are large deformation analysis and nonlinear geometric analysis, the same?

These are some questions I will answer in the Part 2

================================

Part 2

================================

It’s good that you now understand nonlinear geometry.

Do you know why geometric linearity has been used by CAE analysts for so long?

Some reasons are

- Analytical solutions are available for linear problems. This makes it easier for comparison or validation

- The linear FE models require lesser computational resources and are therefore very quick

- Standard analysis procedures dictate the need for geometric linearity

- Linear geometry assumption also facilitates a better conceptual understanding

Let’s move on to the next question?

When should you pay attention to the geometric nonlinearity?

If you think that the stiffness of the geometry changes due to the applied load.

It is difficult to quantify the shape change. I had given four different thumb rules in the previous article. Generally, commercial FEA software brochures have some guidelines. Some blog articles by FEA experts also have these.

Other than the shape change, you should also check how the direction of the load changes as the deformation progresses.

This is applicable especially in the case of large deformations and also depends on the commercial FE solver that you are using.

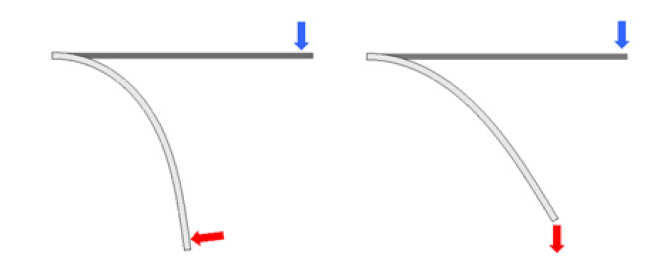

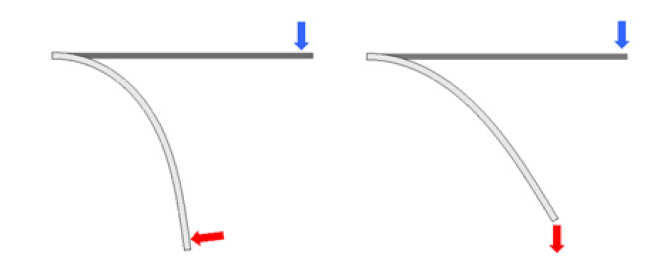

Figure 3: Follower load (left) and non-follower load (right) [1]

As can be seen from the above figure, the follower load changes its direction based on the deformation. Non-follower load doesn’t.

Now consider a pressure vessel subjected to very high pressure. This is bound to produce a shape change. And based on this shape change, the pressure load, which usually acts normal to the walls, needs to follow the deformation.

This in a way, takes us back to the thumb rules. Think carefully before you start the simulation. If you expect the deformations to be large, always consider geometric nonlinearity.

I had a misconception in nonlinear geometry. I used to think that stiffness does not change much when the deformation is small.

I found out, I was wrong after looking at this example where a flat membrane deflects under a pressure load as shown in the figure below.

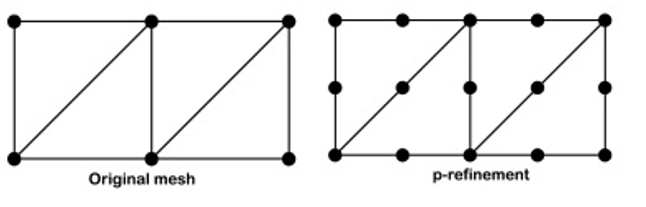

Figure 4: Membrane under pressure load [1]

To quote from [3]

“Initially, the membrane resists the pressure load only with bending stiffness. After the pressure load has caused some curvature, the deformed membrane exhibits stiffness additional to the original bending stiffness (Figure 5). Deformation changes the membrane stiffness so that the deformed membrane is much stiffer than the flat membrane.”

Figure 5: Due to the deformation, it also acquires membrane stiffness. So linear geometric analysis underestimates the stiffness [1].

Concluding remarks:

Never jump into the CAE tool directly. First, understand the problem clearly. List out all the information that is provided and also the information you need. (Material properties, boundary conditions, etc.,). Then try to calmly visualize what the final result would be. I know this is difficult. But with some engineering sense and a rational mind, one can at least foresee the deformation trend based on the load case. This will save you a lot of time and hassles. And also help you in post-processing and report preparation.

Back to square one. Linear or nonlinear geometry? It depends.:) You will have to decide. Have a good time doing that.

Do you also have some interesting examples or experiences with geometric nonlinearity in FEA? Please do write about that in the comments section below. Would love to hear more and learn from you.

Have a great day.

Prost!

~ Renga

References:

[1] https://www.solidworks.com/sw/docs/Nonlinear_Analysis_2010_ENG_FINAL.pdf

[2] https://enterfea.com/nonlinear-flow-chart/

[3] https://www.solidworks.com/sw/docs/Nonlinear_Analysis_2010_ENG_FINAL.pdf

A book on Python Scripting for ABAQUS:

I have written a book that helps you to write Python scripts for ABAQUS in just 10 days.

Why should you buy my book?

Please use the link below to purchase the book.

Crash Course on Python Scripting for ABAQUS: Learn to write python scripts for ABAQUS in 10 days